With a little planning, even older data centers can go green – 5 Steps to a greener data center!

An efficient, well-designed data center is important for every organization; it can reduce down-time, increase output and reduce operation and maintenance costs. Probably the biggest benefit is that a properly maintained data center can save significant capital expenditures by negating the need for upgrades or expansion. According to the International Data Corporation, “Data center managers are seeking energy optimizing solutions that deliver benefits through reducing operating energy costs and increasing data center capacity, which will enable them to extend the life of data centers while deferring new build-out or retrofit costs.”– IDC, 2010

- Take a Look at your Equipment

In a properly managed data center, IT equipment will account for the majority of energy use. Many companies that supply hardware now offer “green”, energy-efficient options. Replacing older hardware can result in significant cost and energy savings. Even if you don’t currently have the resources to replace hardware, ensuring that your current hardware is properly maintained can have a noticeable impact. Since most equipment now includes some type of thermostatic fan control, taking care to provide a clear path through the machine is imperative for optimum operation. Check intake grills for dust or lint accumulations, insure cabling is properly dressed and accessories such as cable management arms, in-rack PDUs, etc. are not blocking any exhaust ports.

- Data Center Airflow

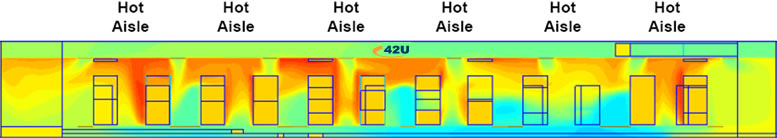

The desired path of air in the data center is out of the air conditioning equipment, through the IT equipment and the back to the air conditioning equipment. There are 2 other paths that the air can take:- Air from the outlet of the air conditioning equipment can return directly to the input, robbing cooling effectiveness and reducing the total capacity of the air conditioning equipment. This effect is called “short cycling”

- Hot air that is exhausted from the IT equipment can find its way back the inlet of that same or adjacent equipment. The resultant temperature of the air ingested can be significantly higher than the cool air delivered by the air conditioning equipment and depends on the amount of mixing that takes place. The result is that the temperature of the air that is delivered by the air conditioning equipment must be lower than that which would be required if the hot air were not being mixed with the cool air. This effect is called recirculation and the net effect is the same as short cycling, the overall cooling capacity of the air conditioning equipment is reduced.

Managing airflow, and ensuring that hot air and cold air are as isolated as possible, can enable significant cooling cost savings. This management starts at the rack where any un-used space above, below or between pieces of IT gear should be blocked off to prevent hot air from leaking back to the front of the rack. Racks should be placed as tightly together as possible with no open spaces in rows which are oriented in a “hot aisle/cold aisle” design. Equipment is placed on racks to ensure that air intake comes from a “cold aisle”, and all output air is expelled into a “hot aisle”.

The unobstructed return of the hot air to the air conditioning equipment is every bit as important as the delivery of cold air. IT equipment rows should be located such that perimeter air conditioning equipment is centered at the end of hot aisles. If there are more hot aisles than air conditioners, placing empty, blanked racks at the end of the row nearest the air conditioner is an effective way to keep the hot air directed properly without affecting operating equipment. In many cases, the air can be further isolated with simple plastic curtains, ensuring that only cold air is supplied to the equipment and equally important, the hot air has a clear path back to the air conditioning equipment.

- Data Center Temperature

Your data center shouldn’t feel like a walk-in freezer; overcooling in data centers is a common problem, and is often the result of inefficient design. Separating the hot and cold air flows, as described above, is a good start to temperature control, but it is also important to understand the needs of your equipment. When choosing a server, pay attention to the operating temperature requirement on the data sheet. Every major equipment manufacturer supports the temperature range recommended by the American Society of Heating, Refrigeration and Air-conditioning Engineers (ASHRAE) which has an upper limit of 77° F. The Sun XFire 2100, for example, can operate in between 41° and 95° Fahrenheit so setting the inlet air temperature to the upper limit of 77° provides both significant operating margin and energy savings. - Where is Your Data Center Going?

When designing, remodeling or even adding a few servers to a data center, it is important to take into account future as well as current loads. How fast is your company growing? When do you expect to update your data center in the future? By planning carefully and employing sophisticated tools such as computational fluid dynamics (CFD) modeling, you can avoid the unintentional creation of cooling issues and even predict the effect of cooling equipment failures. Depending on the operations of your business, you may be able to cycle some servers on a monthly basis; for example, your computing needs may be greatest at the end of the month during financial closes, but you may not need maximum capacity for an entire month. Examining the load of each of your servers throughout the month can result in cost and energy savings and a better understanding of your specific computing needs. - Use Your PUE/DCIE

Your data center’s PUE, or Power Usage Effectiveness, is a metric used to express the energy efficiency of your data center. PUE is equal to: with efficiency increasing as the value approaches 1.(1) DCiE, or data center infrastructure efficiency, is simply the reciprocal of PUE. Knowing your current PUE will allow you to both set goals for and track efficiency improvements within your data center. 42u’s online PUE calculator, found at https://www.42u.com/measurement/pue-dcie.htm, can help you calculate your current PUE and set energy efficiency goals based on cost and energy savings.

with efficiency increasing as the value approaches 1.(1) DCiE, or data center infrastructure efficiency, is simply the reciprocal of PUE. Knowing your current PUE will allow you to both set goals for and track efficiency improvements within your data center. 42u’s online PUE calculator, found at https://www.42u.com/measurement/pue-dcie.htm, can help you calculate your current PUE and set energy efficiency goals based on cost and energy savings.

Conclusion

An efficient data center can save you money and ensure that your business runs smoothly. By understanding your data center environment, you can not only save time and money, but reduce energy consumption and emissions. An efficient data center is not just good for your business and wallet; it’s also the environmentally and socially responsible way to manage your operations.

References

(1) http://www.thegreengrid.org/~/media/WhitePapers/White_Paper_6_-_PUE…